Stainless Steel Upper Mechanical Stirring Bioreactors

- ModelLBR-XSJ Series

- BrandLABOAO

- CustomizedOEM/ODM

- CertificationCE/PED

- Min. Order1 unit

- PortAny port in China

- PackagePlywood case package

DESCRIPTION

Stainless steel shaft coupling drive bioreactors fermenters Main body is made of all stainless steel 316L tank with no dead corners in the tank. It adopts the direct coupling mechanical stirring method driven by the upper/bottom part, which has a simple structure and stable operation. it is with special sampling and discharge valves for fermentation tanks, and seed transfer pipelines. Adopt a large-view tank liquid level observation mirror, 12V safety light, with temperature, PH, DO, defoaming, liquid level interface, inoculation port, refilling port, and multiple spare ports, all welds are firm, neat and beautiful.

FEATURES

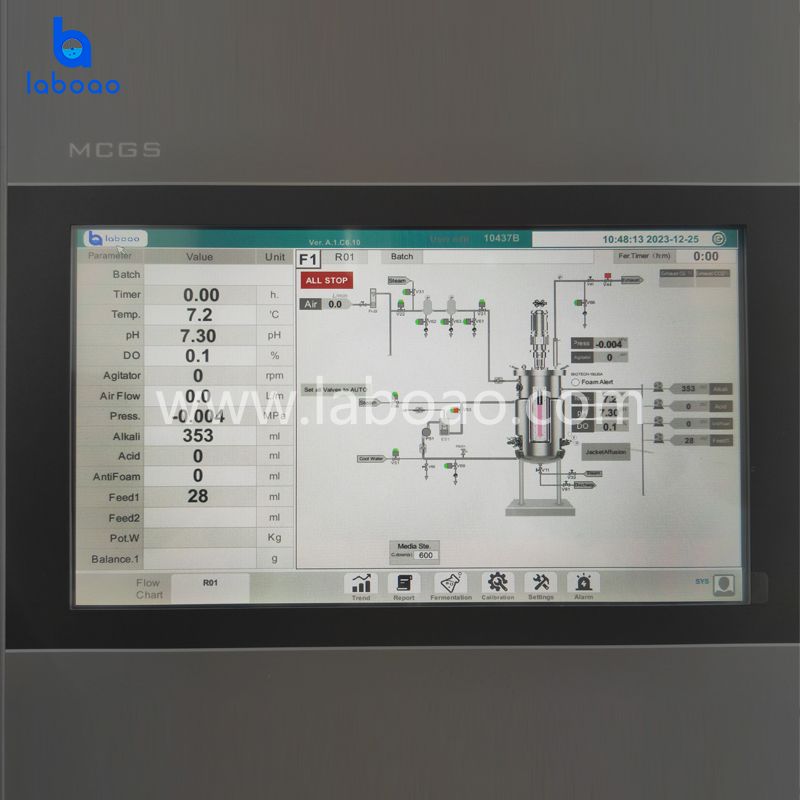

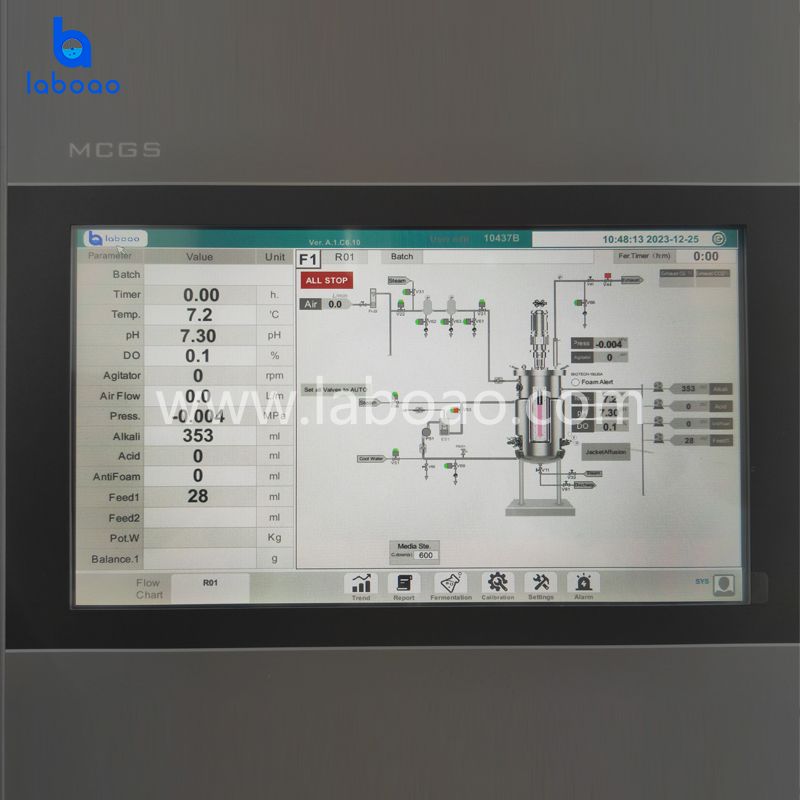

1. It can control the stirring speed, the temperature of the medium in the tank, the Ph value, and the DO value;

2. The upper and lower limits of temperature, rotation speed, Ph value, DO value can be set, and the alarm function of exceeding limit can be set;

3. With over-liquid level alarm and automatic refill function, with over-bubble level alarm and automatic addition of defoamer functions;

4. All alarm accidents can be recorded and consulted;

5. Speed, temperature, Ph value, DO value, etc. can be set to automatic and closed state;

6. The temperature of the medium in the tank, stirring speed, Ph, DO and other parameters can be controlled by setting the curve in sections according to the process requirements;

7. Each parameter has PID adjustment process display, such as setting value, real-time value, PID setting value, upper and lower limit value, curve display, manual/automatic switching, online setting, etc.;

8. The historical data and curves of various parameters can be stored for many years, and the real-time curve can be restored as it is when the power is turned on again;

9. Possess the function of replenishment measurement; regular and quantitative replenishment;

10. The system has a variety of related controls: the related control of speed and dissolved oxygen, the related control of feeding and dissolved oxygen, the related control of feeding and ph, etc.;

11. The system has real-time display, data recording and data analysis of the running process;

12. The parameters of each detection and control loop can be manually set and corrected online on the screen, temperature, DO, PH sensors can be adjusted and adjusted, and the flow rate of each peristaltic pump can be calibrated; the operation has a password protection function, and the password is divided into operations Passwords of the administrator and administrator;

13. Automatically record the start-up time of the fermentation tank, the shutdown time, the number of power outages during automatic operation, the time of power outage, the time of incoming calls, etc.;

14. The software system has adaptive and self-diagnostic capabilities;

SPECIFICATIONS

Model | LBR-XSJ Series |

Volume | 5L/10L/20L/30L/50L/100L/200L/300L/500L/1000L optional |

Diameter to height ratio | 1:2~3 |

Feeding volume | 70% |

Material | Stainless steel 304/316 |

Function | PH/DO/Foam/Temp control |

Pressure | 0.3Mpa |

Sterilization method | Automatic or manual sterilization |

Stirring system | Mechanical sealing system at the top/bottom of the fermenter |

Stirring Speed | in the fermenter: 70~1000rpm±1% |

Temperature detection | Auto control (cooling water+5℃)~65℃±0.1℃ |

pH detection | 2.00-12.00±0.05pH |

DO detection | 0-150±3% |

WHY CHOOSE US

- Factory direct sales with competitive price.

- Premium quality with CE & ISO certification.

- Strong product OEM & ODM customization capability.

- Promise production & on-time delivery.

- Perfect after-sales service, free product accessories.

- 15 years of experience in R&D and production of stainless steel fermenter bioreactor machine.

OUR FACTORY

We have a standard production workshop and a complete production team. They always produce a serious and responsible attitude to produce each product. Our R&D team is made up of multi-aspects professional engineers such as design engineer,technology specialist ,qualified specialist and process control manager, etc. Our qualified specialists strictly realize the process comprehensive supervision based on our quality process control system, which contains products design, research and development, test, production, quality inspection and packaging.

CUSTOMER CASES

Our laboratory instruments and equipment are used in many scientific laboratories, scientific research institutions, universities, hospitals, centers for disease control and other institutions, and are combined with many well-known biopharmaceuticals, new energy, electronics companies, food processing, environmental protection, etc. Enterprise cooperation, our stable and reliable products are exported to more than 120 countries around the world, and have been highly recognized by them, believe LABOAO, we grow together!