Wiped Film Molecular Distillation Equipment For CBD Oil

- ModelLMD-A

- BrandLABOAO

- PortAny port in China

- PackagePlywood case package

DETAILS

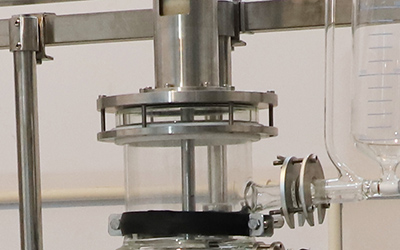

- Main evaporator - jacketed evaporator, serpentine condensation coil to improve condenser area, SS316 with graphite composite material scraper, 300°C high temperature resistance.

- Magnetic coupling system - SUS316L material. High temperature resistant multi-level strong magnetic drive source. Imported wear-resistant high temperature and corrosion resistant bearings from Germany.

- Feeding tank - can customize as per request, such as volume, jacketed type, stainless steel material

- Cold trap - can add dry ice or liqiud nitrogen etc. Also can do OEM.

- Controller - Omron brand temperature controller. Vacumm display with Torr, mBar, Pa unit. Speed setting and display.

- Collecting flask - GG17 high borosilicate glass material, anti-corrosive. With adjustable lifting stand. Heavy and light molecular collecting flask, volume is optiona, material is optional.

DESCRIPTION

Molecular distillation is a distillation method that operates in a high vacuum. At this time, the average free path of the vapor molecule is greater than the distance between the evaporation surface and the condensing surface, so that the difference in the evaporation rate of each group in the material liquid can be used to separate the liquid mixture.

Molecular distillation equipment successfully separates volatile from less volatile components for Oils, Fats, Chemicals, Polymers, Nutraceuticals, Fragrances, etc. with a gentle process, utilizing the thin-film wiping action of feed liquid through a heated cylindrical vacuum chamber with high vacuum (i.e. vacuum distillation/evaporation) to realize distillation function.

FEATURES

1. The distillation temperature is low, and molecular distillation is operated at temperatures far below the boiling point. As long as there is a temperature difference, separation can be achieved. This is the essential difference between molecular distillation and conventional distillation.

2. The vacuum of distillation is high, and the internal vacuum of the molecular distillation device can be obtained. Usually molecular distillation operates at a very low pressure, so the material is not easily oxidized.

3. Distilled liquid film thin, high heat transfer efficiency.

4. The heating time of the material is short, and the distance between the heated liquid surface and the cooled condensation surface is less than the average free path of the light molecule, so the light molecules escaping from the liquid surface reach the condensation surface almost without collision. Therefore, the heating time of the distillation material is short, and the stay time at the distillation temperature is generally between seconds and tens of seconds,

which reduces the chance of thermal decomposition of the material.

5. More separation, molecular distillation can separate conventional materials that are not easily separated.

6. There is no boiling bubbling phenomenon. Molecular distillation is free evaporation on the surface of the liquid layer. lt is carried out at low pressure and there is no dissolved air in the liquid. Therefore, the entire liquid can not be boiled during distillation and there is no bubbling phenomenon.

7. Non-toxic, harmless, no pollution, no residue, can be pure and safe products, and the operation process is simple, less equipment. Molecular distillation can separate materials that are not easily separated by conventional distillation.

8. Molecular distillation equipment cost good, and the molecular distillation device must ensure that the system pressure reaches a high degree of vacuum. The requirements for material sealing are high, and the distance between the evaporating surface and the condensing surface must be moderate. The equipment is difficult to process and the cost is high.

9. The energy consumption of the product is small, because the total thermal loss of molecular distillation is less, and because of the unique structure of the molecular distillation device, the internal pressure is extremely low, and the internal resistance is much smaller than that of conventional distillation so it can greatly save energy consumption.

Advantage:

From the above characteristics of molecular distillation technology, it can be seen that it has the following obvious advantages over conventional distillation technology in practical industrial applications:

1. Molecular distillation provides the best separation method for the separation of high boiling point, thermal sensitivity and oxidizing materials. Because molecular distillation operates at temperatures far below the boiling point of the material, and the material stays for a short time;

2. Molecular distillation can be extremely effective in removing substances in liquids such as organic solvents, odors, etc., which is a very effective method for the decolorization of liquids after solvent extraction;

3. Molecular distillation may selectively evaporate the product of the purpose, remove other impurities, and separate more than two substances at the same time through multistage separation;

4. The fractionation process of molecular distillation is a physical process, which can well protect the separated material from pollution and infringement.

SPECIFICATIONS

Model | LMD-60A | LMD-80A | LMD-100A | LMD-150A | LMD-200A | LMD-230A |

Effective evaporator area (m²) | 0.05 | 0.1 | 0.15 | 0.25 | 0.35 | 0.5 |

Barrel diameter (mm) | 60 | 80 | 100 | 150 | 200 | 230 |

Feeding volume (L) | 1.5 | 1.5 | 1.5 | 2 | 2 | 2 |

Processing flow (kg/h) | 0.1-2.0 | 0.3-4.0 | 0.5-5.0 | 1.0-8.0 | 1.5-10.0 | 2.0-15.0 |

Motor power (W) | 120 | 120 | 120 | 120 | 200 | 200 |

Blade material | SS316L +PTFE | |||||

Lifting for receiving flask | YES (2 SETS) | |||||

Cold trap volume (L) | 2 | 2 | 2 | 2 | 2 | 2 |

Operation temperature | RT ~300°C | |||||

Temperature display meter | Omron brand | |||||

Vacuum degree accuracy | 0.0001Pa | |||||

Frame material | SS304 (SS316 is optional) | |||||

Customized | YES | |||||

Application:

Molecular distillation is used industrially for purification of oils. It is also used to enrich borage oil in γ-linolenic acid (GLA) and also to recover tocopherols from deodorizer distillate of soybean oil (DDSO).

Typical Applications

Fine Chemicals

Separation of nitric acid from organic high boiling liquids

Separation of butane (butyne) diol from high boiling liquids

Recovery of methanol from high boiling liquids

Recovery of xylenol (dimethylphenol) from a purification solution

Removal of hexane from PP and PE waxes

Drying of salt via the evaporation of water and solvent

Separation of phenol from bituminous coal pitch

Distillation of starting products for the production of insecticides

Separation of byproducts in the production of synthetic fibers

Polymers

Distillation of TDI, HDI and MDI (isocyanates)

Final removal of toluene from epoxy resin

Separation of THF from polymers

Distillation of trimethylpropane from high boiling liquids

Recovery of solvents from synthetic resin production

Lactic Acid, starch and sugar

Upgrading and distillation of lactic acid

Upgrading of tartaric acid derivatives

Concentration of sweetening agents

Concentration of modified starch

Pharmaceuticals

Concentration of active ingredient solutions

Distillation of pharmaceutical substances

Upgrading of substances for artificial feeding

Oleochemicals, Fatty Acids,Biodiesel

Separation of dioxin from surfactants

Removal of free fatty acids from mon, di and triglycerides

Distillation of monoglycerides

Distillation of fatty acids from tall oil

Distillation of fatty acid methyl esters

Separation of residual glycerine from residues in biodiesel production (glycerine dryer)

Miscellaneous

Drying of industrial sludge

Drying & pre-concentration of municipal sewage sludge

Drying of hydroxide sludge

Drying of inorganic salt solutions

Drying of preliminary and intermediate products from chemical industry

Drying of suspensions, pastes and moist solids into powder

Drying of lubricants for forging industry

WHY CHOOSE US

- Factory direct sales with competitive price.

- Premium quality with CE & ISO certification.

- Strong product OEM & ODM customization capability.

- Promise production & on-time delivery.

- Perfect after-sales service, free product accessories.

- 15 years of experience in R&D and production of molecular distillation system machine.

OUR FACTORY

We have a standard production workshop and a complete production team. They always produce a serious and responsible attitude to produce each product. Our R&D team is made up of multi-aspects professional engineers such as design engineer,technology specialist ,qualified specialist and process control manager, etc. Our qualified specialists strictly realize the process comprehensive supervision based on our quality process control system, which contains products design, research and development, test, production, quality inspection and packaging.

CUSTOMER CASES

Our laboratory instruments and equipment are used in many scientific laboratories, scientific research institutions, universities, hospitals, centers for disease control and other institutions, and are combined with many well-known biopharmaceuticals, new energy, electronics companies, food processing, environmental protection, etc. Enterprise cooperation, our stable and reliable products are exported to more than 120 countries around the world, and have been highly recognized by them, believe LABOAO, we grow together!