100L Jacketed Glass Reactor

- ModelLGR-100L

- BrandLABOAO

- StockIn Stock

- CustomizedOEM/ODM

- CertificationCE

- Min. Order1 unit

- PortAny port in China

- PackagePlywood case package

DETAILS

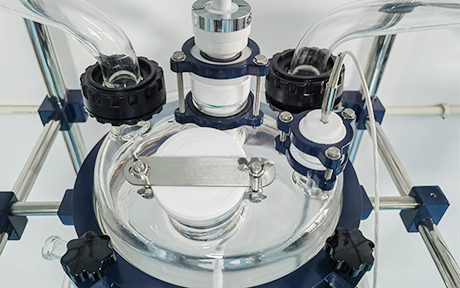

- Total 6 ports on reaction cover, for motor, condenser, temeperature sensor, solid adding, air release, and funnel tank. PTFE sealing.

- High borosilicate glass material, Double layer stirring anchor, PTFE material for anti-corrosion.

- Speed controller, can adjust speed and display temperature.

- Oil vacuum meter, anti-vibration during stirring; High efficient surface area condenser.

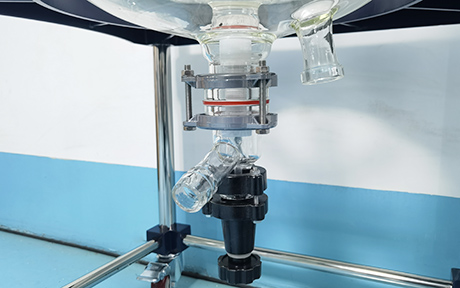

- Discharge valve, easy to discharge materials. PTFE parts for anti-corrosion.

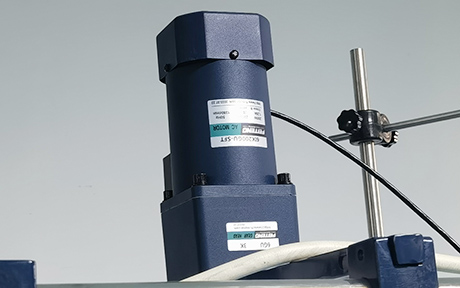

- Stable and reliable low-speed booster motor, electronic stepless speed regulation.

DESCRIPTION

Jacketed Reaction vessels are used for synthetic reaction of different types of materials in a controlled temperature and vacuum environment. Reaction Vessels can be used as an all in one tool for extraction, refinement, distillation, and hemoginization.Consisting of an inner vessel with either one or two jackets, a reactor uses temperature differentials created by a chiller to change it's internal environment. Reaction vessels also operate under vacuum making them ideal for any atmospheric sensitive applications. They can be made out of glass and range in volume from 1L to 200L.

FEATURES

1. A full set of glassware with GG3.3 borosilicate glass that is heat/cold/corrosion-resistant.

2. Wide range of temperature operations, from -60°C to 250°C.

3. Solvent-resistant PTFE seal ensure long time durability and operation, sealing is -0.098Mpa.

4. The PT100 temperature, and is a liquid crystal display. More accurate temperature measurement and more convenient.

5. Frequency control, AC induction motor. Constant speed, brushless, no spark, security and stability, and continuous work.

6. Heavy duty stainless steel supporting framework with lockable casters for mobility and stability. (whole support and glass vessel shipped pre-assembled)

7. Rugged stainless steel reinforced PTFE stirrer with anchored agitator, suitable for a wide range of viscous materials. multi-layer stirring blades is optional.

8. The bottom flange discharge port with a Teflon value, aluminum parts flange fixed.

SPECIFICATIONS

Model | LGR-100L | |

Kettle volume | 100L, inner diameter 465mm, outer diameter 510mm, inner length 696mm | |

Jacketed volume | about 25L | |

Voltage/frequency | 220V/50HZ | |

Stirring power | 200W 1/3 | |

Stirring speed | 0-450r/min | |

Temperature range vessel can bear | -80 ℃ to 250 ℃ | |

Temperature accuracy | ±1℃ | |

Vacuum degree | 0.098Mpa | |

Cover diameter | Φ340mm | |

6ports of cover | Stirring port | Φ60mm flange port |

Condenser port | 50# ball mill port | |

Constant pressure funnel port | 40# standard port | |

Relief port | 34# standard port | |

Temperature measure port | Φ45mm flange port | |

Solid feeding port | Φ80mm flange port,inner diameter Φ60mm matched with PTFE cover | |

Stirring paddle | Φ17*1200H(mm), leafing 240mm | |

Condenser size | Φ120*600H(mm), down with Φ60mm flange port | |

Condensation area | 0.5㎡ | |

Reflux elbow | upper with Φ60mm flange port,left with 50# ball mill plug | |

Constant pressure funnel | 2L, upper with 29# standard port matched with glass plug, down with 40# standard plug | |

Relief valve | 34# standard plug valve,vent nozzle (pagoda connector), outer diameter 12mm | |

In and out circulation port of the sandwich | Φ45 flange port matched with ring flange, 6 points outside the wire adapter | |

Baiting port | Φ75mm flanger port,Φ42mm baiting port,inclined discharging port, (pagoda connector)Φ34mm,from floor 350mm | |

Vacuum suction nozzle | padoga connector,outer diameter 12mm | |

In and out circulation nozzle of condenser coil | padoga connector,outer diameter 15mm | |

Overall dimension (W*L*H) | 950*750*2390mm | |

Net weight | 95kg | |

Packing dimension | 1920*720*970mm,1.34m³ | |

Packing weight | 152kg | |

WHY CHOOSE US

- Factory direct sales with competitive price.

- Premium quality with CE & ISO certification.

- Strong product OEM & ODM customization capability.

- Promise production & on-time delivery.

- Perfect after-sales service, free product accessories.

- 15 years of experience in R&D and production of jacketed glass reactor machine.

OUR FACTORY

We have a standard production workshop and a complete production team. They always produce a serious and responsible attitude to produce each product. Our R&D team is made up of multi-aspects professional engineers such as design engineer,technology specialist ,qualified specialist and process control manager, etc. Our qualified specialists strictly realize the process comprehensive supervision based on our quality process control system, which contains products design, research and development, test, production, quality inspection and packaging.

CUSTOMER CASES

Our laboratory instruments and equipment are used in many scientific laboratories, scientific research institutions, universities, hospitals, centers for disease control and other institutions, and are combined with many well-known biopharmaceuticals, new energy, electronics companies, food processing, environmental protection, etc. Enterprise cooperation, our stable and reliable products are exported to more than 120 countries around the world, and have been highly recognized by them, believe LABOAO, we grow together!