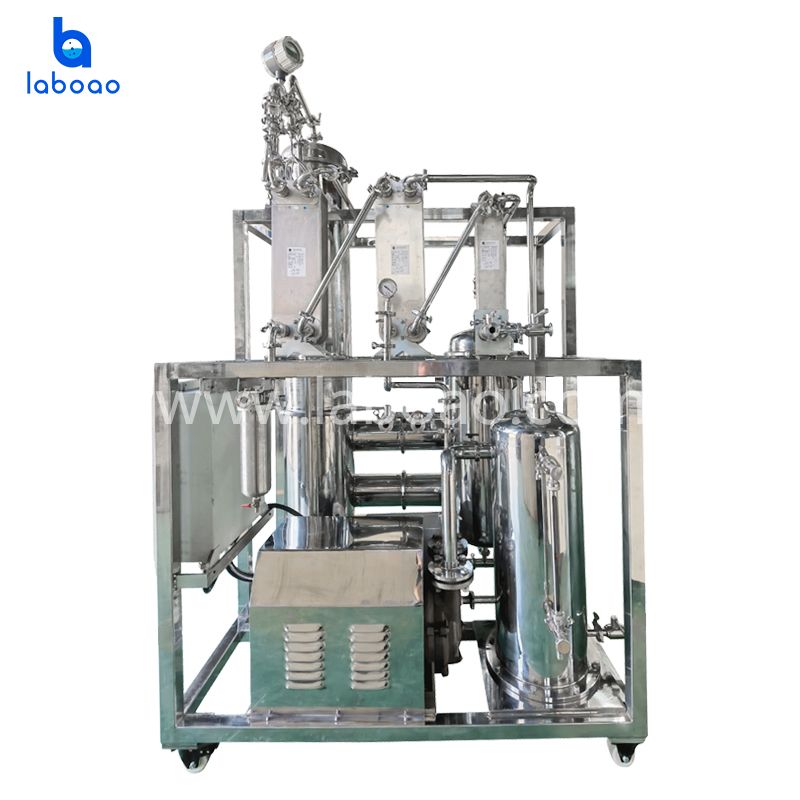

Lab Scale Falling Film Evaporator For Ethanol Recovery

- ModelFFE-250

- BrandLABOAO

- PortAny port in China

- PackagePlywood case package

DETAILS

- Feeding port with filtration system, which can do primary filtration when feeding sample.

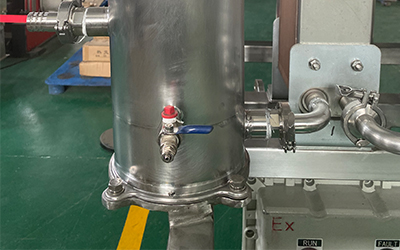

- Explosion proof control box. One button starts and stop. With lamp light alarm for running and fault.

- High condensation efficiency heat exchanger, improve heat transfer efficiency.

- Flow glass sight and flow meter, can observe the sample process condition at any time.

- Explosion proof circulating pump and water circulating vacuum pump are both covered by stainless steel, which is more safety and nice shape.

- Transfer tank connect with cryogenic chiller for ethanol recovery. Including liquid level gauge and filter, which can see the collecting liquid level and do filtration again before recovery.

DESCRIPTION

FFE-250 falling film evaporator is an industrial device to concentrate solutions, especially with heat sensitive components and recover solvents, like ethanol, hexane, heptane, etc. The fluid will create a film along the tube walls, progressing downwards (falling) - hence the name. It is specifically suited to process the products with a low viscosity and a low tendency for fouling.

In general the evaporation takes place inside the vertical tubes, which is called shell-and-tube heat exchanger, crowned by a proprietary liquid distribution device. The fluid distributor is designed carefully in order to ensures an efficient and uniform distribution of the liquid to all the tubes along which the product flows as a continuous film falls, driven by gravity.

The whole solvent recovery system not only includes falling film evaporator, but also equips circulation heater (steam generator as an option), water cooling tower, circulation chiller, vacuum pump and all accessories.

FEATURES

1. 90% - 95% single pass solvent recovery efficiency.

2. Durable S304/S316 sanitary stainless steel construction.

3. Continuous feeding and discharging with optional liquid transfer pumps.

4. Optional upgrade to engineering peer review, GMP and UL standards.

5. Short residence time for the protection of heat sensitive components.

6. Real-time monitoring of vacuum level, temperature and feeding speed.

7. Continuous feeding and discharging with optional liquid transfer pumps.

8. Small footprint with large capacity, 250L/h(ethanol).

9. Turnkey system with supporting chiller, heater or steam generator, vac pumps, etc.

10. Compatible with multiple solvents, like ethanol, hexane, heptane, etc (factory adjustment needed).

11. Dual stage plate heat exchangers to be compatible with water cooling tower for lower equipment and power cost.

SPECIFICATIONS

Model | Description | Size(mm) | Weight(kg) | |||

FFE-250 | Evaporation capacity | 250L/H | 1200*900*3000 | 600 | ||

Working power | Heating Power | 48 KW | ||||

Cooling Power | 11.05 KW | |||||

Pump Power | 5.5 KW | |||||

Connectors | Inlet Joint | 25 Φ | 50.5 Clamp | |||

Solvent Outlet | 25 Φ | 50.5 Clamp | ||||

Product Outlet | 25 Φ | 50.5 Clamp | ||||

Vacuum Outlet | 25 Φ | 50.5 Clamp | ||||

Chiller Inlet | 25 Φ | 50.5 Clamp | ||||

Chiller Outlet | 25 Φ | 50.5 Clamp | ||||

Heater Inlet | DN25 Flange | |||||

Heater Outlet | DN25 Flange | |||||

WHY CHOOSE US

- Factory direct sales with competitive price.

- Premium quality with CE & ISO certification.

- Strong product OEM & ODM customization capability.

- Promise production & on-time delivery.

- Perfect after-sales service, free product accessories.

- 15 years of experience in R&D and production of falling film evaporator machine.

OUR FACTORY

We have a standard production workshop and a complete production team. They always produce a serious and responsible attitude to produce each product. Our R&D team is made up of multi-aspects professional engineers such as design engineer,technology specialist ,qualified specialist and process control manager, etc. Our qualified specialists strictly realize the process comprehensive supervision based on our quality process control system, which contains products design, research and development, test, production, quality inspection and packaging.

CUSTOMER CASES

Our laboratory instruments and equipment are used in many scientific laboratories, scientific research institutions, universities, hospitals, centers for disease control and other institutions, and are combined with many well-known biopharmaceuticals, new energy, electronics companies, food processing, environmental protection, etc. Enterprise cooperation, our stable and reliable products are exported to more than 120 countries around the world, and have been highly recognized by them, believe LABOAO, we grow together!